Shining a Light on HMI vs DCS

When comparing an HMI (Human-Machine Interface) and DCS (Distributed Control System), the choice largely depends on your industrial needs. For basic processes and centralized data visualization, HMIs excel. However, for larger facilities requiring advanced process control and dealing with substantial I/O points, opt for a DCS.

Key Differences Between HMI and DCS

- HMI is used for data visualization and monitoring, while DCS excels in process control for larger facilities.

- DCS efficiently manages extensive I/O points, crucial for advanced process control. HMI offers fewer capabilities for this purpose.

- Industries such as water treatment and power generation use both, but DCS is more predominant due to its advanced process control abilities.

- Modern HMIs leverage touch screens and mobile devices for increased accessibility, while DCS focuses on control, reporting, and process management.

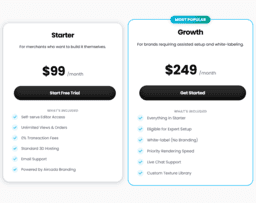

| Comparison | HMI | DCS |

|---|---|---|

| Definition | User interface connecting a person to a system, focusing on data display, production tracking, operational oversight | Automated control system distributing functions across numerous elements in a process |

| Usage Industries | Energy, food and beverage, manufacturing, oil and gas, power, recycling, transportation, water/wastewater | Power generation, oil and gas, water treatment, pharmaceuticals and biotech, manufacturing, infrastructure |

| Main Roles | Operators, system integrators, control system engineers | Centralized operator supervisory control |

| Market Growth | Significant evolution especially in areas of touch-screen HMIs, mobile HMIs, and edge-of-network HMIs. AR/VR technologies being explored | Anticipated market growth to $23.2 billion by 2026 |

| Modern Technologies Impact | Modern HMIs are extending to edge-of-network HMIs, aiding operators by providing data access and visualization from field devices. AR/VR also being explored | DCS uses set configuration tools for database management, control logic, graphics, and system security |

| Interactive Elements | PLCs and input/output sensors | Engineering workstation, operating station, process control unit, communication system, smart devices |

| Key Benefits | Improvements in industrial processes through data digitizing and centralizing | Increases safety, enhances production efficiency, ease of maintenance throughout plant life cycle |

| Modern Implementations | Data from local HMIs is being sent to the cloud for remote access and analysis | DCS supports modifications, upgrades, integration with existing industrial architecture |

What Is HMI/SCADA (Human-Machine Interface/ Supervisory Control and Data Acquisition) and Who’s It For?

HMI/SCADA are interconnected systems essential for modern industrial operations. HMI is an operator interface or dashboard – an interface between humans and machines. SCADA is a control system that compiles data and manages processes at an industrial level. They are extensively used in industries such as energy, manufacturing, food and beverage, recycling, and water/wastewater.

This technology holds great importance for system integrators, control system engineers, and operators who interact with HMIs to oversee KPIs, track production time, monitor machine inputs and outputs. It also enables the collection and display of data, even remotely, promoting improved decision-making processes.

Pros of HMI/SCADA

- Improves industrial processes through digitizing and centralizing data.

- Offers remote monitoring and data accessing.

- Broadens application with compatibility with AR and VR technologies.

- Enhances decision-making processes in industrial settings.

Cons of HMI/SCADA

- Limited functionality without a change in mindset among employees

- An upgrade might require significant investments in new technology.

What Is DCS (Distributed Control System) and Who’s It For?

A Distributed Control System (DCS) is an automated control system distributing control elements across different factors. Utilized across diverse industries, it is designed to manage and control complex applications. The users of DCS range from operators in emerging process industries to engineers in power generation, biotech or pharmaceutical manufacturing.

The structural design of DCS, including an engineering workstation, operating station, and communication system, ensures optimal operations’ efficiency. The DCS market is projected to grow up to $23.2 billion by 2026, signifying the technology’s increasing value and application.

Pros of DCS

- Allows individual control, reporting, and monitoring components in process plants.

- Reduces installation costs and enhances reliability.

- Optimizes interaction among controllers and enhances production efficiency.

Cons of DCS

- Less effective for real-time control actions compared to programmable logic controllers (PLCs).

- Might need substantial capital for modifications and upgrades.

Decision Time: HMI or DCS?

After a systematic breakdown of HMI and DCS, the verdict hangs in the balance. But one’s choice fundamentally lies in the specific needs of the audience.

Control system Engineers & System Integrators

For careers revolving around process management, HMI brings an impressive arsenal to the table. With its superior visualization, monitoring capabilities, and compatibility with PLCs, HMI delivers unrivaled control over data and operation management. Its steady transformation into touch-screens and mobile devices even allows instant remote monitoring and data access capability.

Industrial Plants and Large Enterprises

Sizable multicultural enterprises stand to gain more from the DCS. With its decentralized control principle and the ability to manage, control and monitor massive I/O points, the DCS is a powerhouse for enhanced process control. Moreso, DCS enhances safety, boosts production efficiency, and eases maintenance throughout the plant life cycle.

Adopters of Modern Tech (AR/VR Creators)

For tech hawkers driving the future through AR/VR, HMI becomes more appealing. Modern HMI extends to AR and VR technologies, visualizing data or manufacturing functions. These advancements entwine perfectly with tech innovators, fostering a conducive environment for their creativity.

The contrast between HMI and DCS lies in their unique areas of mastery. HMI excels in data visualization and control, while DCS shines in managing and controlling large-scale processes. Your choice ultimately depends on your requirements. Remember, the choice of technology should empower you, not restrict you.